Custom Pultrusion: Tailoring Composites to Your Specifications

Custom Pultrusion: Tailoring Composites to Your Specifications

Pultrusion is a manufacturing process that permits the creation of composite products with consistent cross-sectional shapes. It is widely made use of in various markets, including construction, aerospace, auto, and marine. While pultrusion supplies a series of typical profiles, custom pultrusion takes it an action better by tailoring composites to your certain needs.

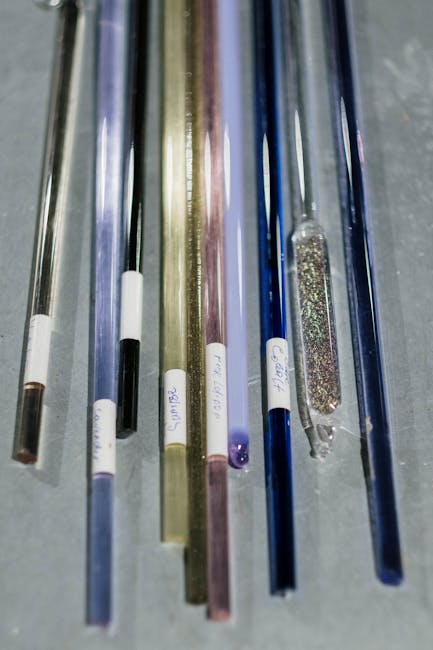

Typical pultrusion includes drawing continuous fiber reinforcements, such as fiberglass, carbon fiber, or aramid, via a resin bathroom and afterwards through a warmed die. The material treatments as the composite product goes through the die, causing a final product with improved toughness, resilience, and various other preferable properties.

Customized pultrusion permits you to go beyond off-the-shelf profiles as well as create composite products that meet your distinct job needs. Whether you require a specific shape, size, mechanical residential or commercial properties, and even color, personalized pultrusion can provide the best remedy.

Among the key benefits of custom pultrusion is the capacity to enhance the product’s efficiency for particular applications. By thoroughly choosing the type and also orientation of the reinforcing fibers, in addition to the type of material matrix, you can attain the wanted mix of stamina, rigidity, thermal resistance, and also chemical resistance. This degree of modification makes certain that completion item meets or surpasses the requirements of your specific application.

In addition to performance optimization, custom-made pultrusion also makes it possible for efficient use materials. By customizing the shape and size of the composite account to your application, you can lessen waste and decrease overall expenses. This degree of modification likewise permits combination of extra attributes, such as inserts, fixtures, or other components, directly right into the pultruded profile during the manufacturing process, getting rid of the requirement for added assembly actions.

Custom pultrusion provides limitless opportunities for advancement and analytic throughout a wide range of markets. Whether you need complex structural accounts for constructing construction, light-weight elements for aerospace applications, corrosion-resistant components for chemical handling, or any kind of other customized compounds, the capability to tailor the pultrusion process makes certain that you obtain the best remedy for your job.

Customized pultrusion takes the benefits of pultrusion to the following level by enabling you to customize composite materials to your specific specs. With the capacity to optimize efficiency, produce special sizes and shapes, and also incorporate extra features, custom pultrusion uses unrivaled adaptability and also effectiveness in composite production. Whether you are trying to find improved toughness, light-weight construction, resistance to extreme environments, or any other particular demand, personalized pultrusion can provide the ideal service for your project.